Procurement

Securing a stable supply of parts and materials is one of key elements of product safety and quality management. LG Energy Solution puts in place various strategies to mitigate risk associated with disruption in parts and materials sourcing. Potential emergency cases are categorized by factor that causes supply chain disruption, including natural disaster, workplace accident, suppliers’ management issue such as bankruptcy, layoff or strikes, geopolitical events and related price fluctuation. For each category of emergency case, a formalized process and manual is put in place that encompasses case classification, reporting protocol, operation of emergency taskforce, and mitigation and remediation planning. Mitigation measures are planned in a phased manner – in the short-term, mitigation measures include temporary sourcing of alternative, production plan adjustment; in the mid- to long-term, mitigation measures vary ranging from dual sourcing, alternative/new supplier identification, to the change of manufacturing site. The category-specific processes and manuals are reviewed and updated on a regular basis to ensure effectiveness of product safety and quality management process and to minimize any adverse impact and prevent recurrence of such event.

Development

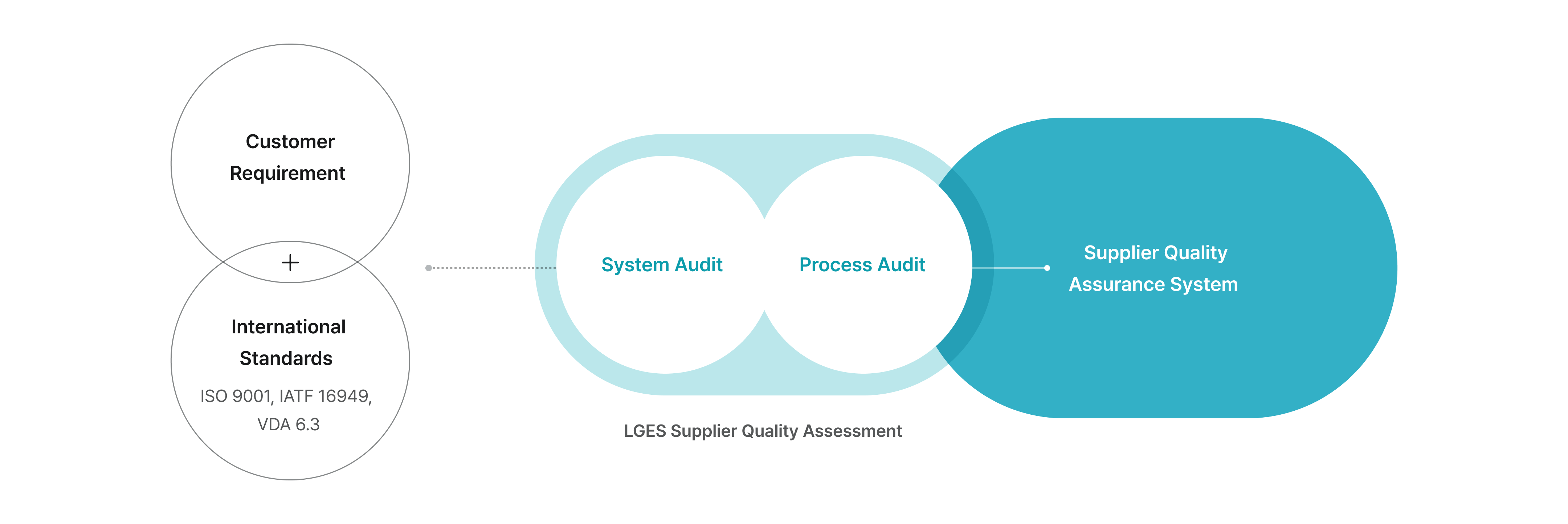

At the product development stage, LG Energy Solution follows a rigorous ‘Product Quality Planning Process’ to ensure the design of products meets customers' quality requirements and international standards. With in-house capacity to test product performance, safety, reliability from the design to materials & parts approval phases, we identify and mitigate potential or emerging quality and safety concerns in a preemptive manner. Each of newly developed products, before mass production, should undergo relevant international certification process.

Comprehensive Product Quality and Safety Assurance

LG Energy Solution is committed to ensuring that its products meet the highest standards of quality and safety throughout their lifecycle. This is demonstrated through rigorous product reliability, environmental, and safety testing during the development phase, followed by regular inspections during mass production phase. Reliability testing ensures product performance consistency during its intended usage period. Environmental testing evaluates a product’s ability to function in conditions like extreme temperatures, humidity, vibration, and shock. Safety testing is performed to verify the product's resilience in abnormal situations that may arise during its usage period. It simulates scenarios, including collision, drop, short circuit, overcharge and over-discharge. Through these comprehensive testing protocols, LG Energy Solution guarantees that its products are safe, reliable, and of the highest quality for end customers.

Production

At LG Energy Solution, we maintain strict quality control measures throughout the production process, conducting thorough inspections of all parts and products at each step. We have put in place various risk mitigation process such as dual sourcing, to mitigate potential risks caused by unexpected changes in the project volume and/or in supply chains. Further, to mitigate potential risk caused by unexpected issue or disruption in the production line, we secure backup manufacturing sites. This helps to maintain operational reliability and business continuity.

Delivery

At LG Energy Solution, outgoing quality controls are conducted in accordance with quality assurance protocols tailored to the respective customer requirements. We adhere to stringent transportation and storage standards, carefully considering product specifications and logistical conditions to ensure optimal quality. The packaging design takes into account factors that may affect product safety and quality, such as temperature and humidity variations and potential external impacts during delivery. In addition, a varied range of robust supply chain stability management strategies are in place to mitigate potential risks such as a sudden surge in customer demand and raw material supply imbalances. These include dual sourcing, securing external warehousing, utilizing Vendor Managed Inventory (VMI), and optimizing safety stock.