LG Energy Solution is dedicated to establishing a circular battery ecosystem through the reuse, diagnostics, sorting, refurbishing, and recycling of End-of-Life batteries. We are committed to developing business models the optimize these processes.

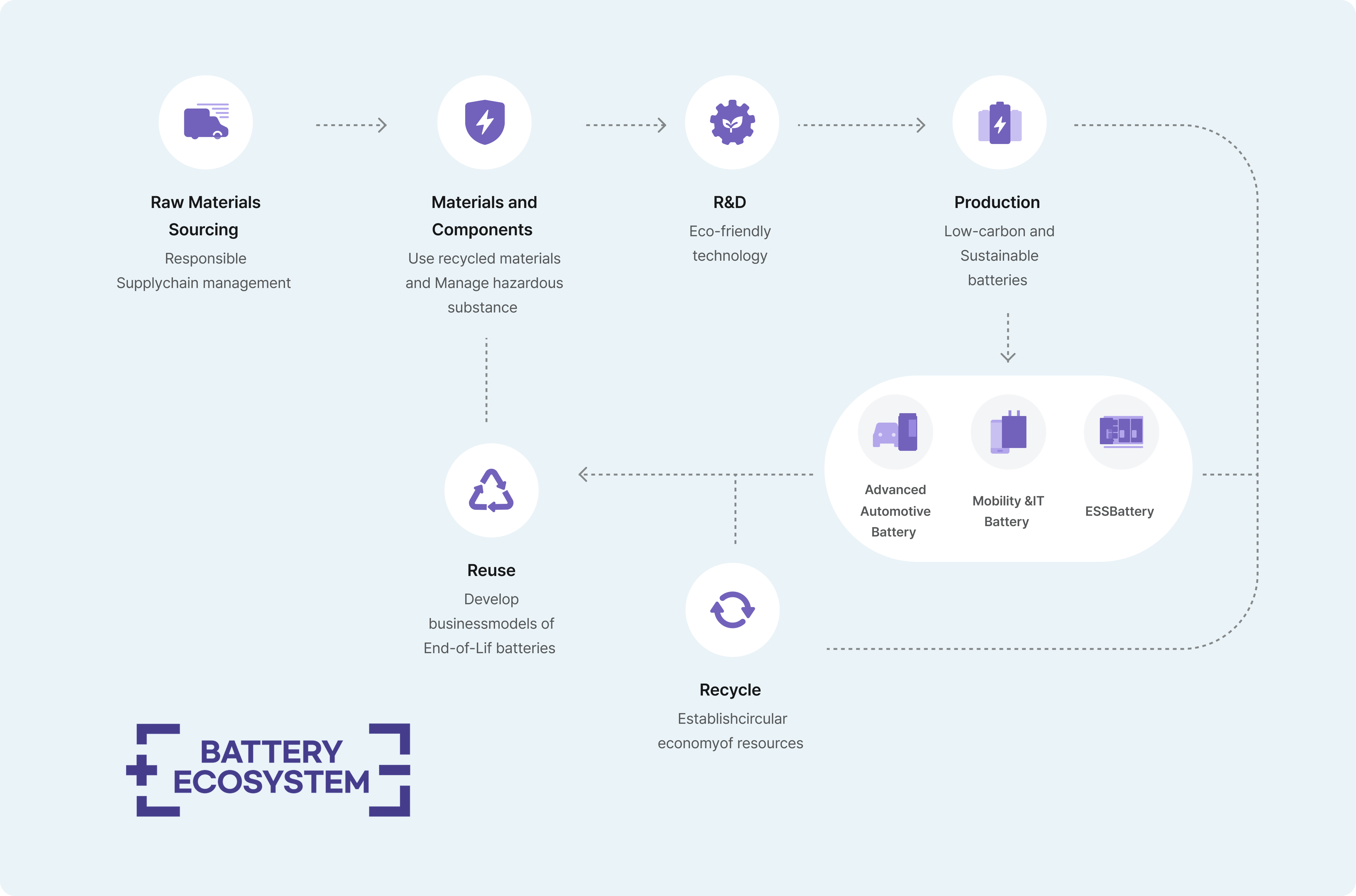

LG Energy Solution builds a circular battery ecosystem in line with

carbon neutrality and drives sustainable growth across diverse industries.

LG Energy Solution is dedicated to establishing a circular battery ecosystem through the reuse, diagnostics, sorting, refurbishing, and recycling of End-of-Life batteries. We are committed to developing business models the optimize these processes.

As policies and regulations regarding batteries are being introduced in Europe, the US, China, and other countries, the EU requires that batteries placed on the EU market demonstrate environmental friendliness and safety throughout their entire lifecycle, from production to recycling, through the EU Battery Regulation. Accordingly, batteries sold in Europe have different minimum standards for recycled materials and mandatory collection rates for each type of battery, including portable, LMT (Light Means of Transport), industrial, and electric vehicles.

To comply with these emerging regulations, we are building the closed-loop resource circulation system that covers the entire value chain, from the production of raw materials for batteries to consumption, disposal, and recycling. In addition, we are collaborating with local partners to reuse and recycle End-of-Life batteries and recycle process scrap that meets global environmental standards.

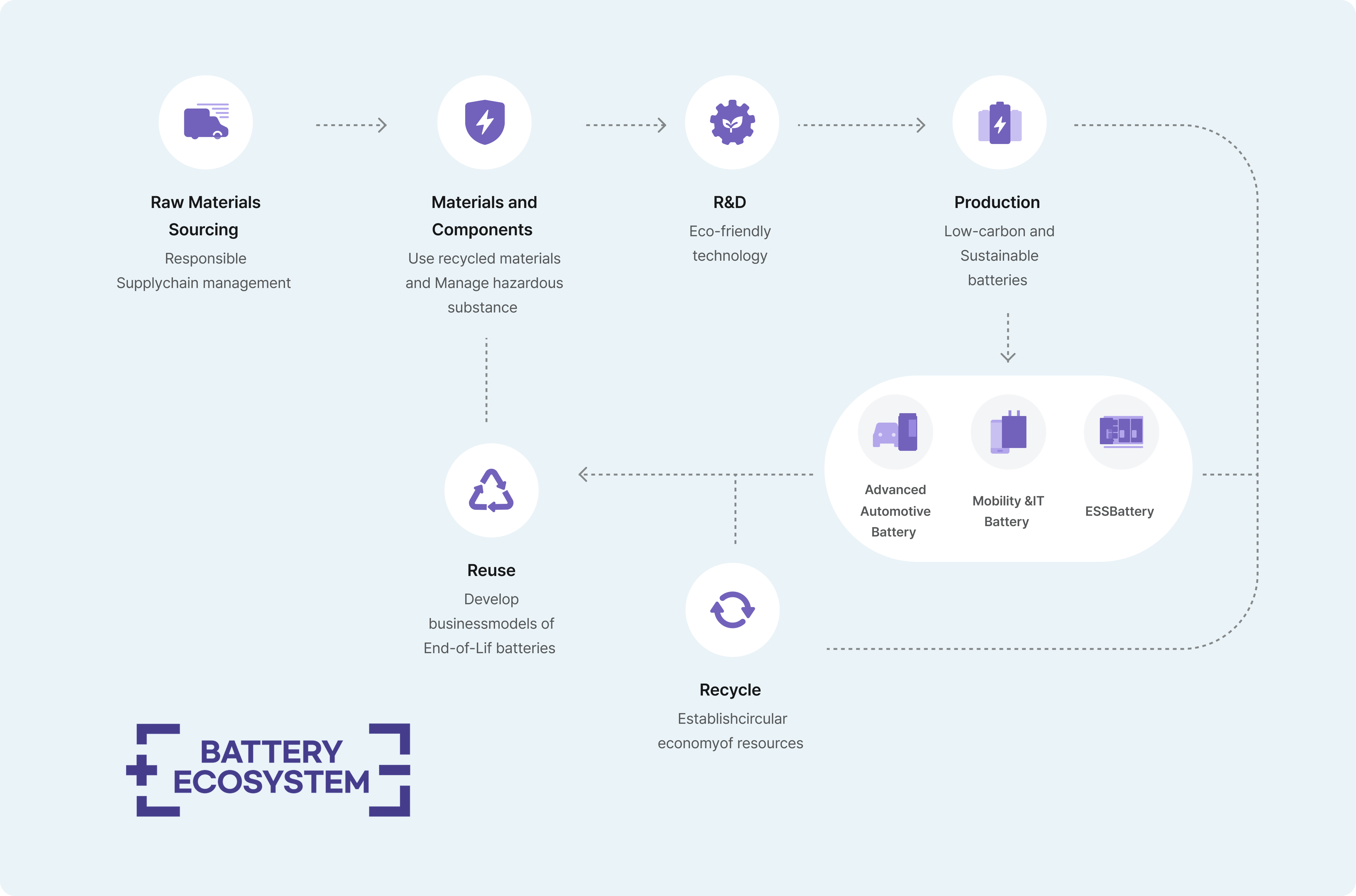

LG Energy Solution is strengthening its battery resource circulation system in response to the recycled metal requirements of the EU Battery Regulation. we place particular emphasis on increasing the recycling rates of key battery materials such as lithium, nickel, and cobalt.

This approach helps reduce waste generated during the battery production process and maximizes resource recirculation.

Since the supply of recycled metals from production scrap alone does not satisfy regulatory standards, we are expanding our recycling network and enhancing cooperation across Europe, North America, and Asia. Starting in 2027, LG Energy Solution plans to operate localized pre-processing facilities through partnerships with local companies at global sites. This Closed-Loop system secures a stable supply of recycled metals

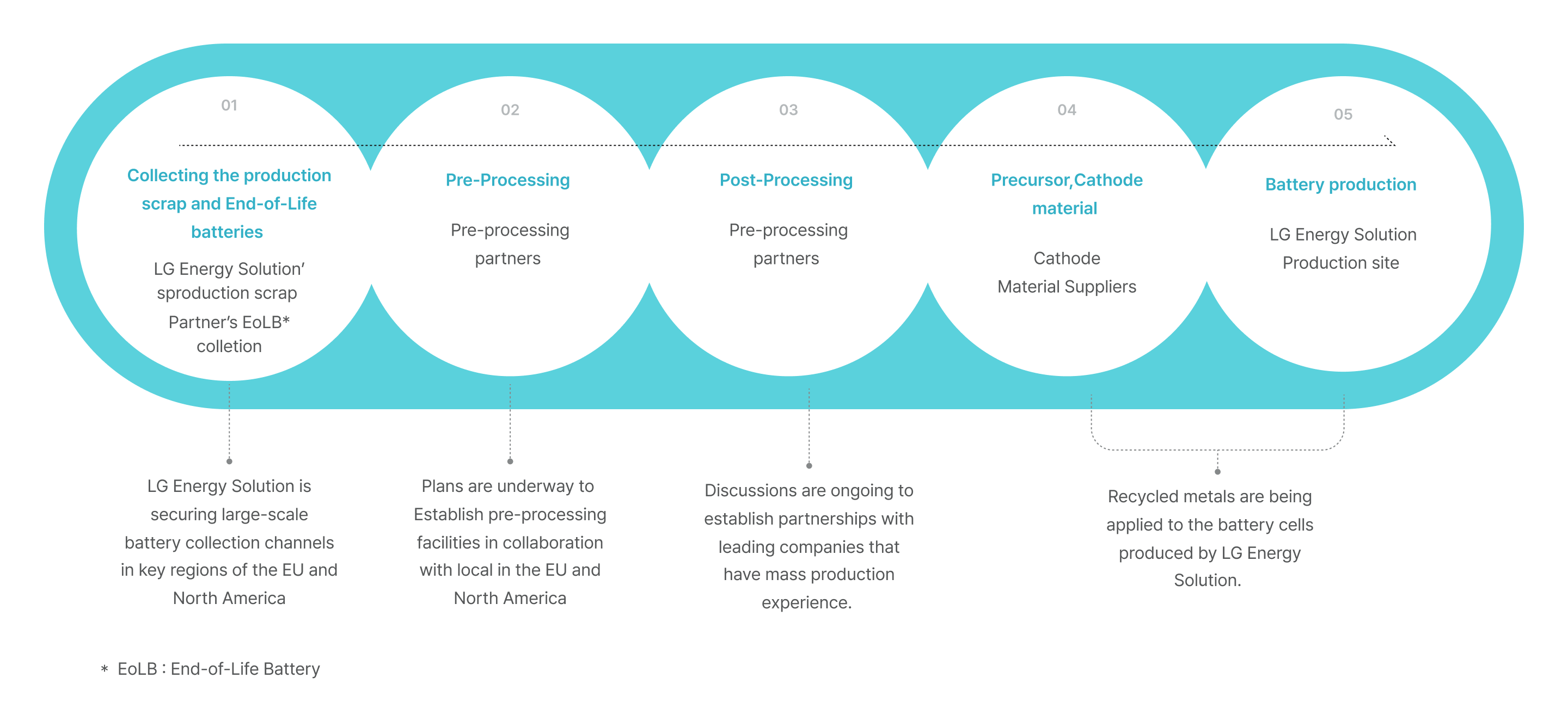

End-of-life batteries not fit for automotive use are collected through a regional collection system and assessed for determination of its second life application. Reusable batteries are transported and stored separately.

Reusable batteries are classified based on their conditions – through physical and chemical analysis and residual capacity prediction – and second life applications

Reusable batteries are tailored to meet the technical requirements and safety standards of different applications Cost competitiveness is ensured by optimal desgins that prioritize safety, and efficiency of manufacturing procedures.

Refurbishing is similar to repair process. Degraded components within the collected battery are identified and replaced to restore the performance. Repurposing is system re-building process based on new applications which are different from original purpose, mostly requiring less demanding performance than EV. This stage includes not only solution development to being satisfied with expected system performance, quality standards, certification regulations required to be cost competitive, but also emphasis on safety through optimal design and streamlining of manufacturing processes.

LG Energy Solution is leading a range of strategic initiatives globally to create proven battery reuse solutions and propose innovative business models. Examples of these projects include: A battery reuse Energy Storage System (ESS) linked to an electric vehicle (EV) fast-charging station at Ochang Energy Plant 1 in Chungcheongbuk-do, South Korea, A grid-scale battery reuse ESS project in North America, Development of battery reuse ESS systems for UPS (Uninterruptible Power Supply) and telecommunications, A commercial battery reuse ESS (BESS) project with a partner company in Norway. Through these trials and ongoing refinements, we are steadily building up our battery reuse expertise. We also play an role in shaping policies and frameworks for End-of-Life batteries by region, collaborating with key customers and industry partners.

A device that provides stable power supply in the event of power outages or faults, ensuring uninterrupted electricity flow.

Installation and Operation of Reuse ESS System in Texas through Collaboration with a North American Partner

48V Backup Power Reuse Pack Utilizing Recovered Automotive Battery Modules

LG Energy Solution collects and uses personal information as follows for the purpose of providing downloads and responding to inquiries.

Name, Email, Company Name

Consent to Receive Marketing Information

Retained for one (1) year from the date of collection, then destroyed

You may refuse to provide consent; however, in such cases, access to certain content may be restricted.

LG Energy Solution uses personal information to provide useful information such as promotions and newsletters:

Name, Email, Company Name

Consent to Receive Marketing Information

Retained for one (1) year from the date of collection, then destroyed

You may refuse to consent; however, in such cases, content may not be provided.

LG Energy Solution uses cloud systems to manage your information securely. Accordingly, your personal information may be transferred overseas.

Microsoft

United States

Name, Email, Company Name

Data storage and system operation

Transmitted over network immediately upon collection

Retained for one (1) year from the date of collection, then destroyed

You may refuse to consent; however, in such cases, content may not be provided.