LG Energy Solution is developing sodium-ion battery technology with excellent high-rate characteristics and low-temperature output, while achieving differentiated cost competitiveness. Starting with 12V products, we aim to secure a leading position in the ESS and future mobility

LG Energy Solution is a total energy solutions company that builds

an energy ecosystem with customer-centric advanced technology,

global integrated operations, and sustainable growth.

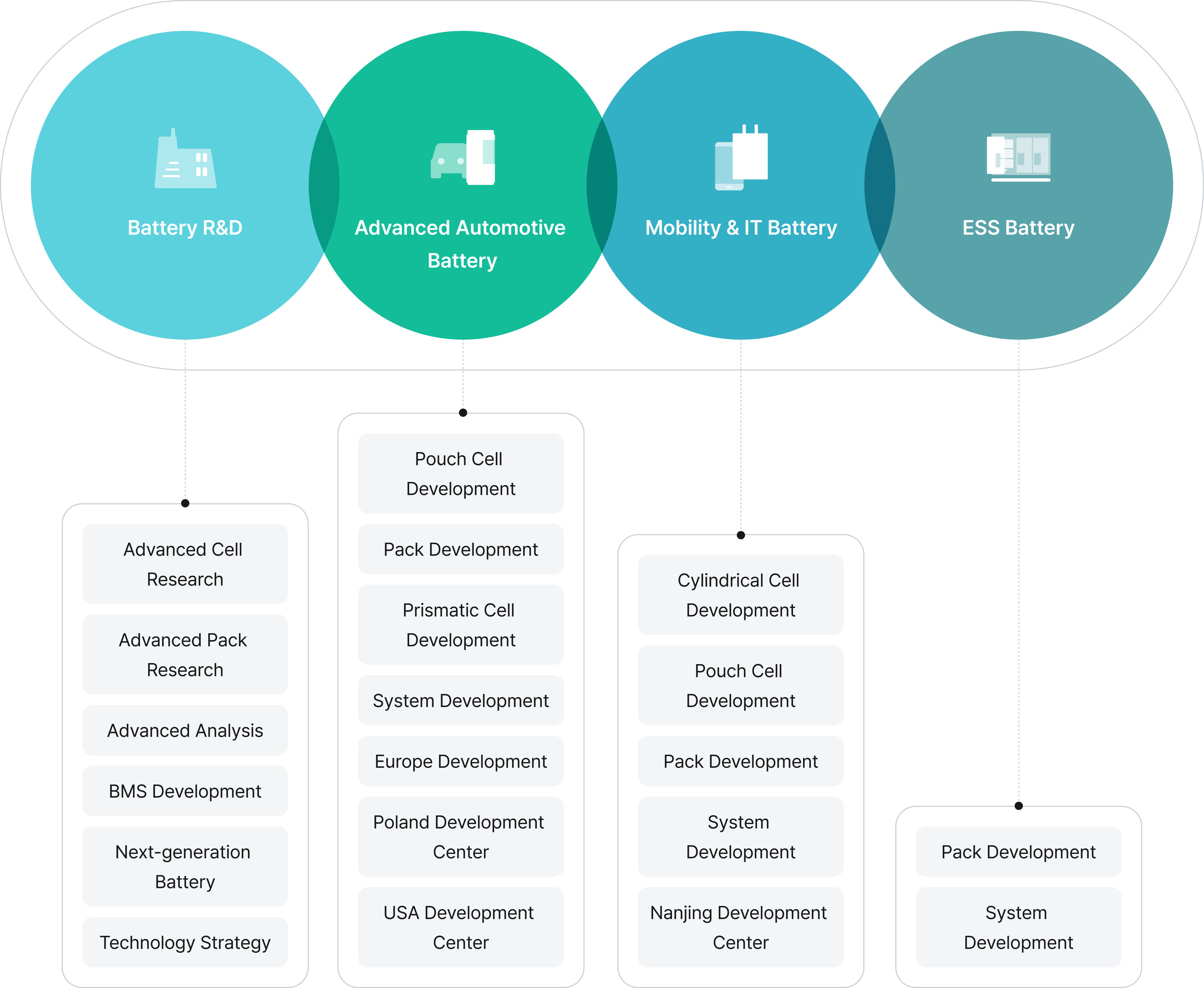

R&D Status

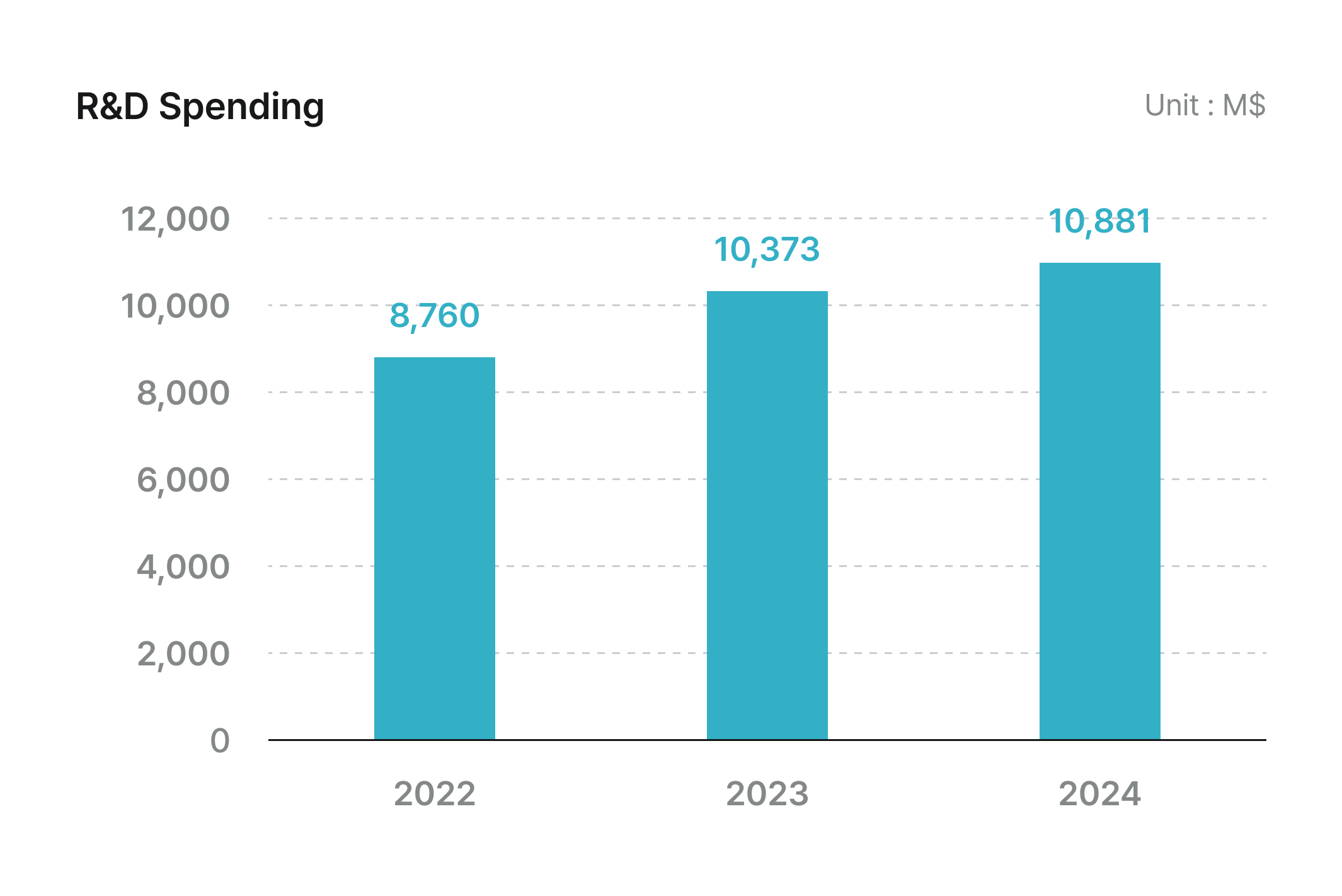

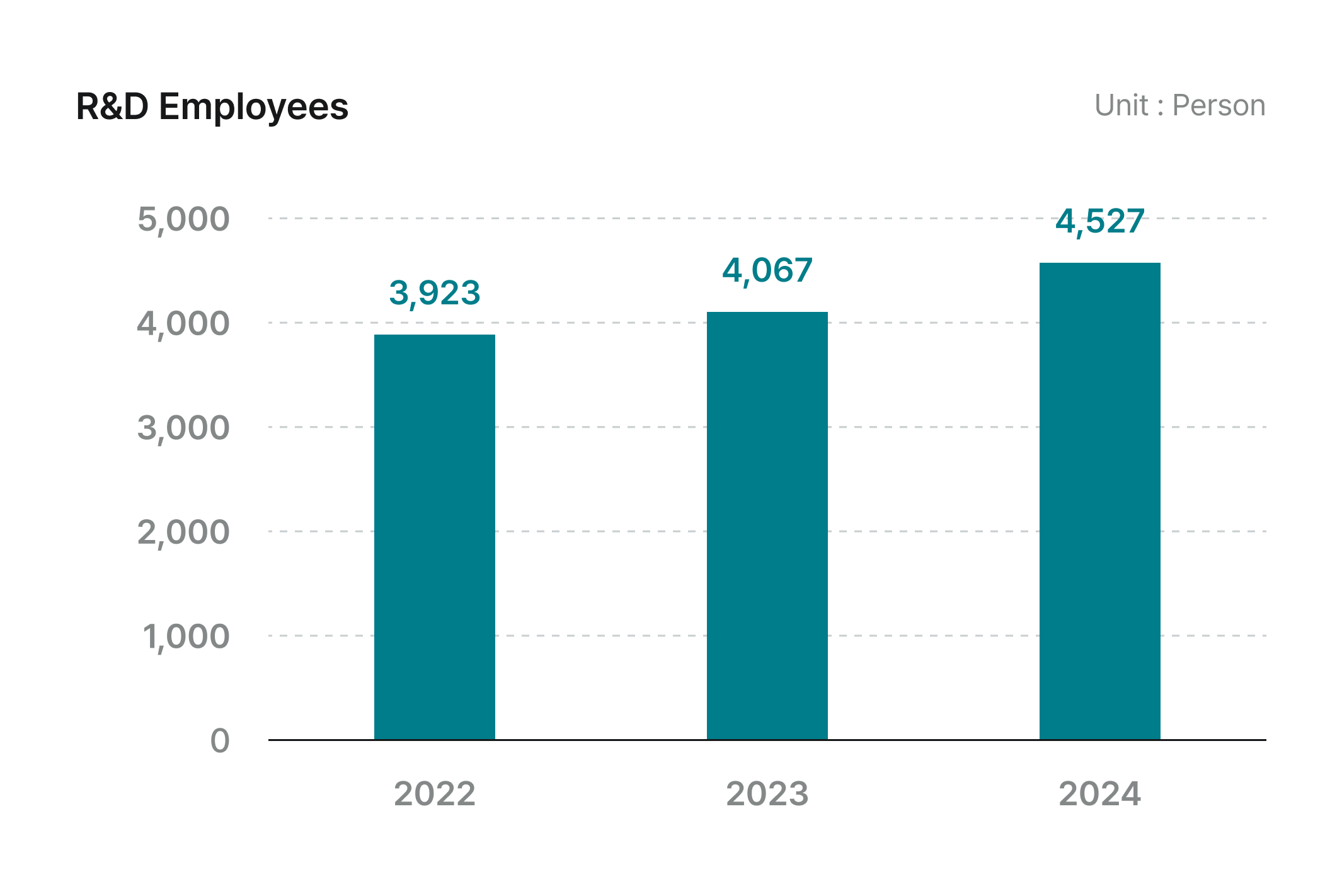

LG Energy Solution strives to contribute to the upcoming era of eco-friendly energy by developing next-generation batteries with core technologies and intellectual property rights accumulated through proactive and continuous investment in R&D.

R&D Organization

R&D Investment

Intellectual Property Rights

(as of December, 2024)

-

Global Patents

69,631

-

Korea

23,635

-

Overseas

45,996

R&D Field

We are constantly making efforts to discover new promising opportunities through continued investment in R&D and securing and converging advanced core technologies. In particular, we are concentrating on developing new products and enhancing the competitiveness of our current business, focusing on core technologies such as next-generation high-capacity/high-safety materials and advanced battery manufacturing processes.

Major Fields of Research

Battery materials

- Materials

- Process

- Next Generation Battery

- Preliminary Research

- Pack

- BMS

- Future Technology Study

Advanced Automotive Battery

- PEV

- PHEV battery

- HEV battery

Mobility & IT Battery

- EV

- LEV

- Power Tools

- IT Devices

ESS Battery

- Grids

- Residential

Next Generation Battery

LG Energy Solution is accelerating the development of an innovative next-generation battery portfolio powered by cutting-edge technologies. By developing safer, more efficient, high-performance, and cost-effective next-generation batteries, we aim to bring the future mobility era closer.

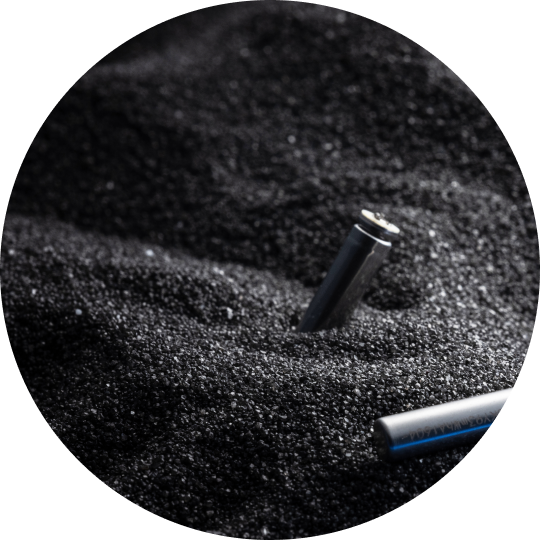

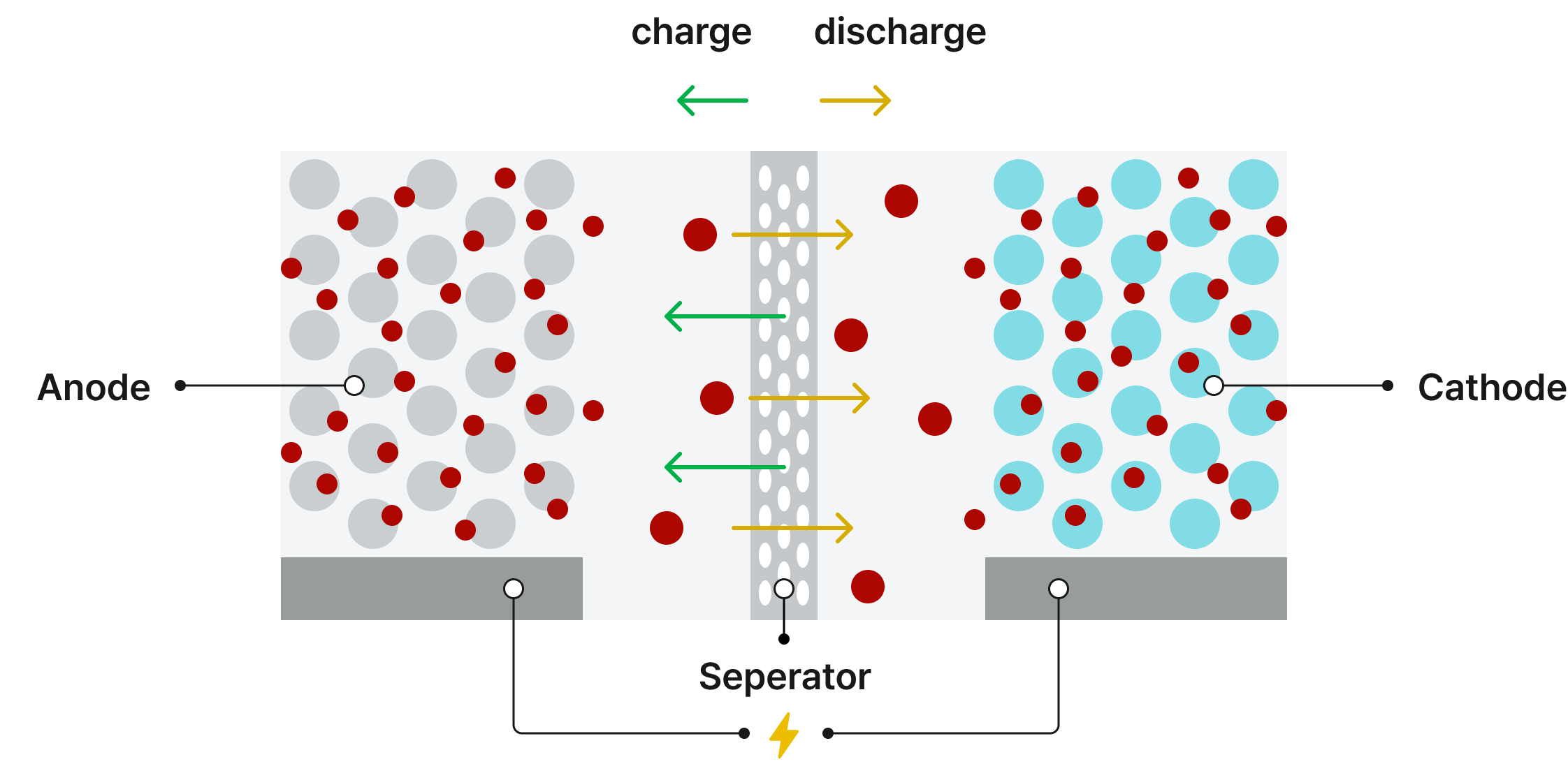

Sodium-ion Battery

Sodium-ion batteries use sodium, which is abundantly available on Earth, instead of lithium, thereby reducing raw material costs while delivering outstanding high-rate performance and low-temperature output.

Key Features of Sodium-Ion Battery Technology

(Commercialization planned for 2027)

High Cost

Competitiveness

Achieves cost advantage by using sodium, priced at less than 1/100 of lithium

Excellent High-Rate Performance and Low-Temperature Output

Incorporates hard carbon materials and sodium-ion electrolytes to deliver outstanding high-rate characteristics and low-temperature output

Sustainable

Materials

Ensures sustainability by utilizing globally abundant sodium resources and adopting a cobalt-free composition

Expanding Applications Based on Excellent High-Rate Performance and Low-Temperature Output

By leveraging the outstanding high-rate performance and low-temperature output of sodium-ion batteries, LG Energy Solution aims to achieve differentiated cost competitiveness and expand from 12V products to the ESS and affordable EV markets.

12V Battery

Affordable EV

Energy Storage System

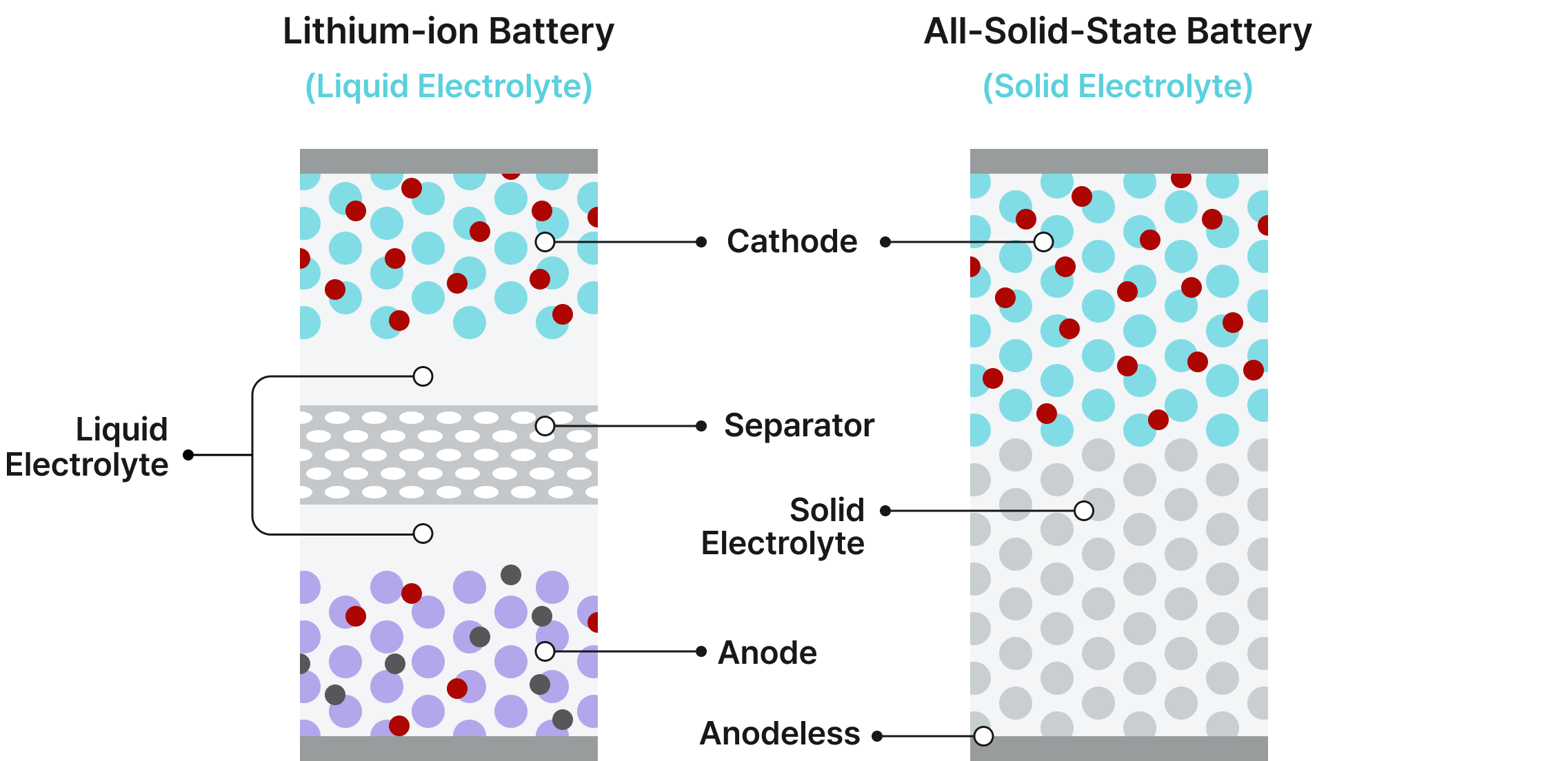

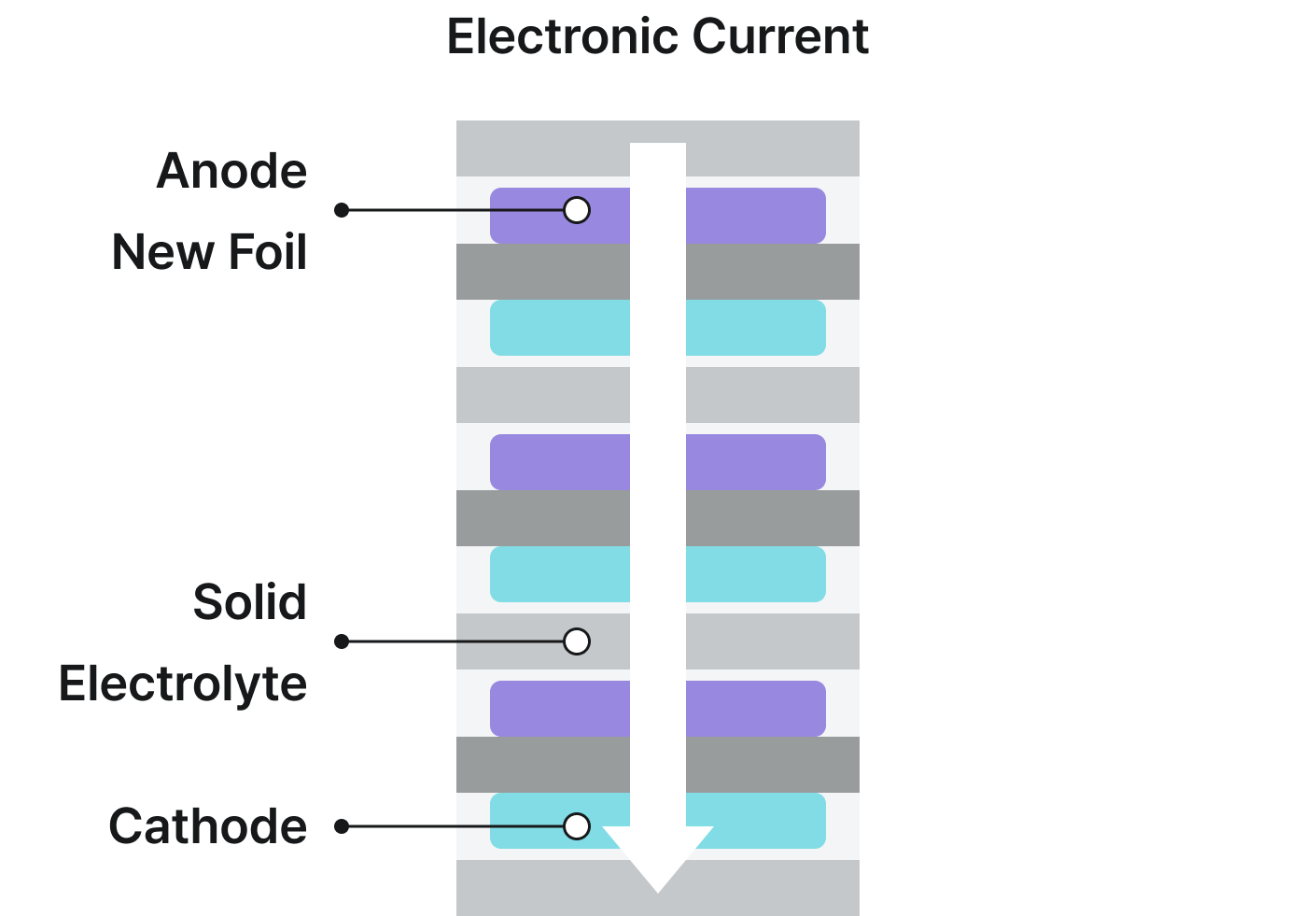

All-Solid-State Battery

LG Energy Solution is developing high-performance sulfide-based all-solid-state battery technology with high energy density, safety, and excellent high-temperature durability, with plans for rapid commercialization. Beyond premium high-performance EVs, its applications will expand to electric ships, ESS, and other industries, opening new possibilities for next-generation batteries.

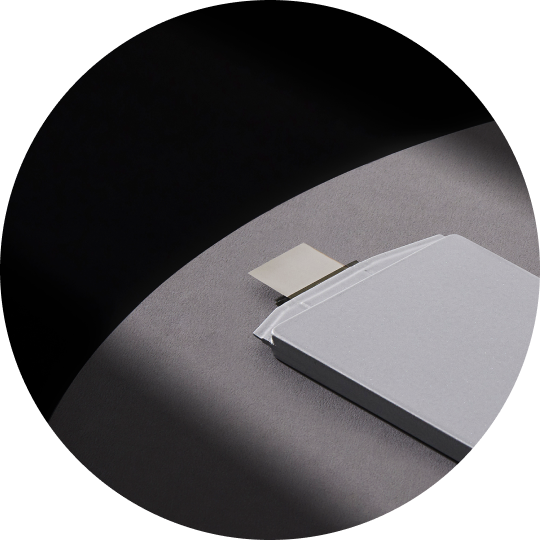

All-solid-state batteries are secondary batteries that use solid electrolytes between the cathode and anode, offering lower risk of combustion, higher energy density, and the ability to achieve high capacity.

Key Features of All-Solid-State Battery Technology

(Commercialization planned for 2029)

Enhanced Safety

Improved safety and thermal runaway control through the application of solid electrolytes

High Energy Density

Achieves high energy density by applying an anodeless (no-anode) design

Fast Charging

Enables ultra-fast charging in under 20 minutes based on excellent high-temperature durability

Expanding Applications Based on Safety and High-Temperature Durability

With the superior safety and high-temperature durability of all-solid-state batteries, safety can be enhanced at the system level while simplifying thermal management systems. Leveraging these advantages, applications will expand from high-performance premium EVs to electric ships and ESS.

High-Performance EVs

Electric Vessel

Energy Storage System

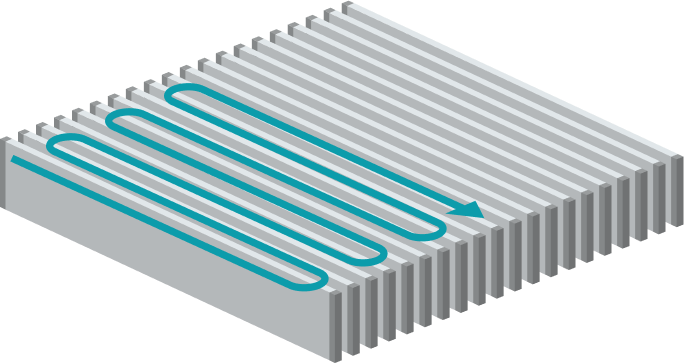

Bipolar Battery

LG Energy Solution also aims to deliver more efficient and innovative battery solutions for future mobility by advancing bipolar battery technology, which enables high-voltage systems with simplified structures, thereby improving cost competitiveness and significantly extending driving range.

Bipolar batteries achieve high voltage through series connections within the cell, thereby enhancing driving range and cost competitiveness at the battery system level.

Key Features of Bipolar Battery Technology

(Commercialization planned for 2028)

Improved Cost Competitiveness

Maximizes cost competitiveness by applying low-cost materials, implementing high-energy cells, and simplifying processes and pack structures

Enhanced Space Utilization

Simplifies internal pack structures through a large-area bipolar design, improving space efficiency.

Strengthened Safety

Improves safety through the application of semi-solid electrolytes

Enhanced Space Utilization with Differentiated Cell Structure

Bipolar batteries enable high-voltage system implementation with a simplified structure, improving cell space utilization at the pack level while reducing the number of components. This simultaneously enhances energy density and reduces manufacturing costs. Building on these strengths, LG Energy Solution plans to expand applications beyond affordable EVs to commercial vehicles such as electric trucks, where high-voltage implementation and space efficiency are critical.

Bipolar Battery Serial Connection Structure

Lithium-ion BatteryParallel Connection Structure

Vertically Stacked Cell Blocks

Bipolar BatterySerial Connection Structure

Horizontally Stacked Cell Blocks

Applications

EV

Electric Truck

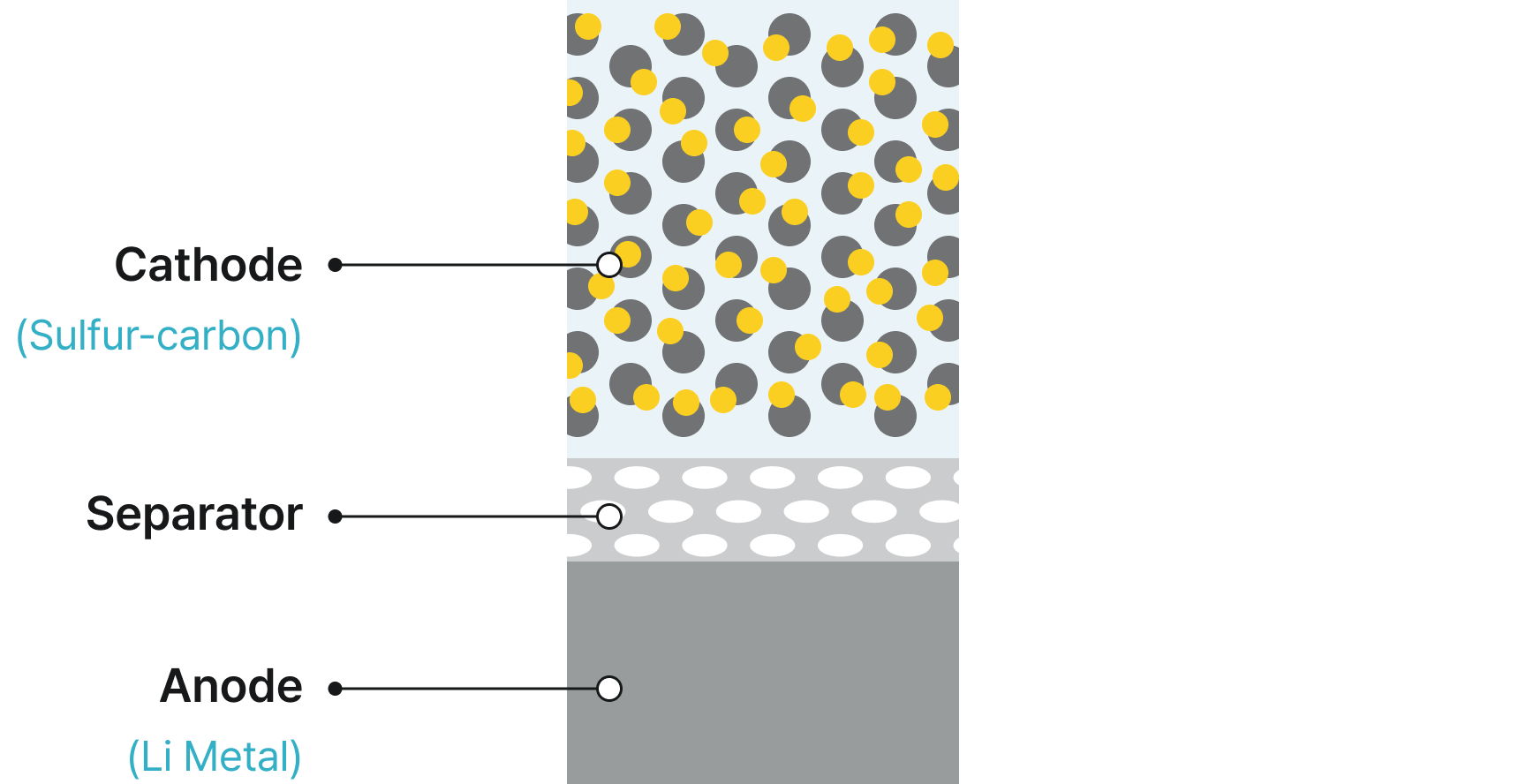

Lithium-Sulfur Battery

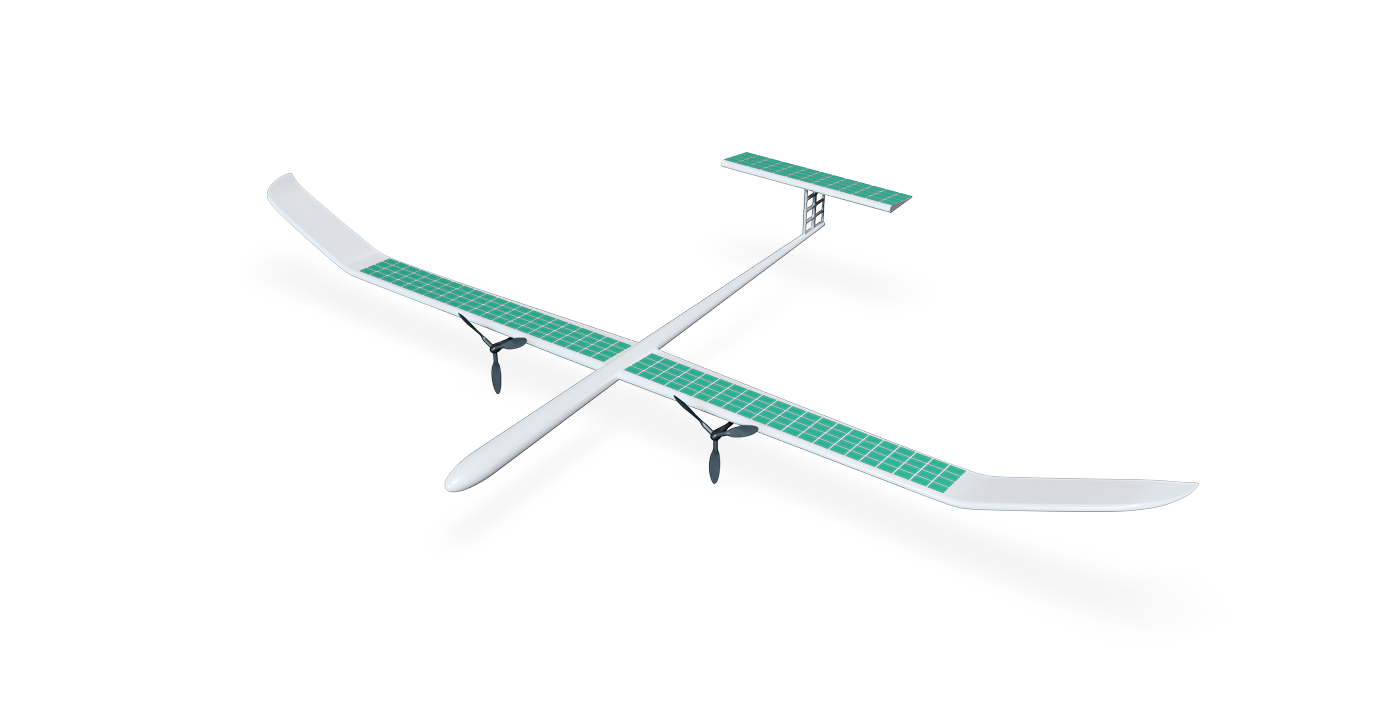

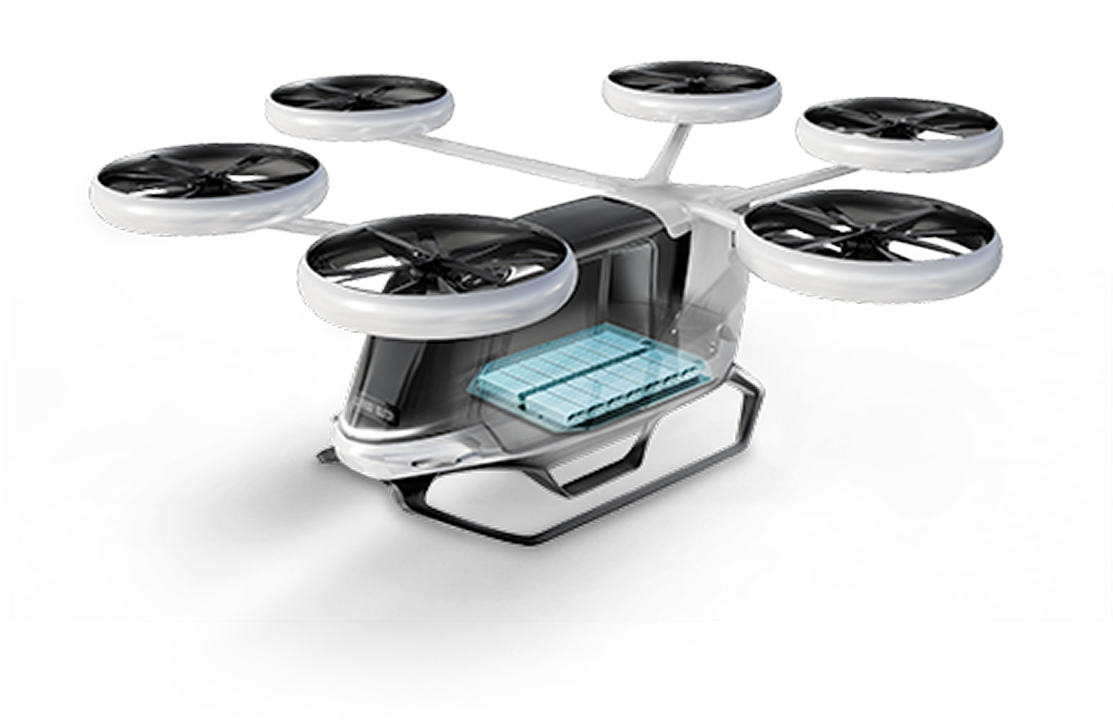

LG Energy Solution is advancing the commercialization of lithium-sulfur battery technology, which delivers high energy density per unit weight, making it lightweight yet capable of strong instantaneous power output. This technology will drive innovation in future modes of transportation such as aircraft and Urban Air Mobility (UAM).

Lithium-sulfur batteries use lightweight materials such as sulfur–carbon composites for the cathode and lithium–metal for the anode, achieving more than twice the energy density of conventional lithium-ion batteries.

Key Features of Lithium-Sulfur Battery Technology

(Commercialization planned for 2029)

Enhanced Energy Density per Unit Weight

More than twice the gravimetric energy density of lithium-ion batteries, enabling significantly greater storage capacity per unit weight

Outstanding Lightness

Applies lightweight materials such as sulfur and carbon instead of metal oxides for the cathode

High Cost Competitiveness

Uses abundant and low-cost sulfur to reduce battery manufacturing costs

Pioneering New Markets with Lightness and Cost Competitiveness

With superior lightness and cost competitiveness, lithium-sulfur batteries will first be applied to high-altitude unmanned aerial vehicles (UAVs) and UAM, and later expand into the broader aviation mobility market with significant growth potential, leading the electrification of future transportation.

High-Altitude UAV

UAM

Successful Flight Test of Lithium-Sulfur Powered High-Altitude UAV (2020)

In 2020, LG Energy Solution (then LG Chem) successfully demonstrated the potential of lithium-sulfur battery technology by powering a high-altitude, long-endurance solar UAV developed by the Korea Aerospace Research Institute. The test flight lasted 13 hours, including 7 hours in the stratosphere at an altitude of 12–22 km.

Open Innovation

LG Energy Solution is expanding collaborations with academia, industry, and startups

to resolve challenging obstacles and accelerate the technological development of batteries.

Open Submission for Start-Ups & SMEs (OSS)

Looking for technology collaboration partners.

“Open Submission for Start-Ups & SMEs” is LG Energy Solution’s open innovation channel, designed to foster ongoing collaboration with start-ups and enterprises on diverse topics. Proposals submitted through this program are matched with internal experts, reviewed, and provided with opportunities for technology evaluation and collaboration. Based on the results of the Proof of Concept (PoC), further opportunities may be offered, including joint R&D with LG Energy Solution, equity investment, and partnership agreements.

The Battery Challenge (BC)

Growing together with start-ups.

A biennial event, hosted by LG Energy Solution and run by American startup accelerator New Energy Nexus, where selected startups cooperate to conduct joint R&D and venture projects, resulting in a win-win growth.

Catalog Download

Consent to Collection and

Use of Personal Information

LG Energy Solution collects and uses personal information as follows for the purpose of providing downloads and responding to inquiries.

-

Items Collected

Name, Email, Company Name

-

Purpose of Use

Consent to Receive Marketing Information

-

Method of Provision

Email

-

Retention & Use Period

Retained for one (1) year from the date of collection, then destroyed

-

Right to Refuse and Disadvantage

You may refuse to provide consent; however, in such cases, access to certain content may be restricted.

Consent to Receive

Marketing Information

LG Energy Solution uses personal information to provide useful information such as promotions and newsletters:

-

Items Collected

Name, Email, Company Name

-

Purpose of Use

Consent to Receive Marketing Information

-

Method of Provision

Email

-

Retention & Use Period

Retained for one (1) year from the date of collection, then destroyed

-

Right to Refuse and Disadvantage

You may refuse to consent; however, in such cases, content may not be provided.

Consent to Overseas

Transfer of Personal

Information

LG Energy Solution uses cloud systems to manage your information securely. Accordingly, your personal information may be transferred overseas.

-

Recipient

Microsoft

-

Country

United States

-

Items Transferred

Name, Email, Company Name

-

Purpose of Transfer

Data storage and system operation

-

Method of Transfer

Transmitted over network immediately upon collection

-

Retention & Use Period

Retained for one (1) year from the date of collection, then destroyed

-

Right to Refuse and Disadvantage

You may refuse to consent; however, in such cases, content may not be provided.