Carbon Neutrality across the Entire Value Chain by 2050

LG Energy Solution builds a circular battery ecosystem in line with

carbon neutrality and drives sustainable growth across diverse industries.

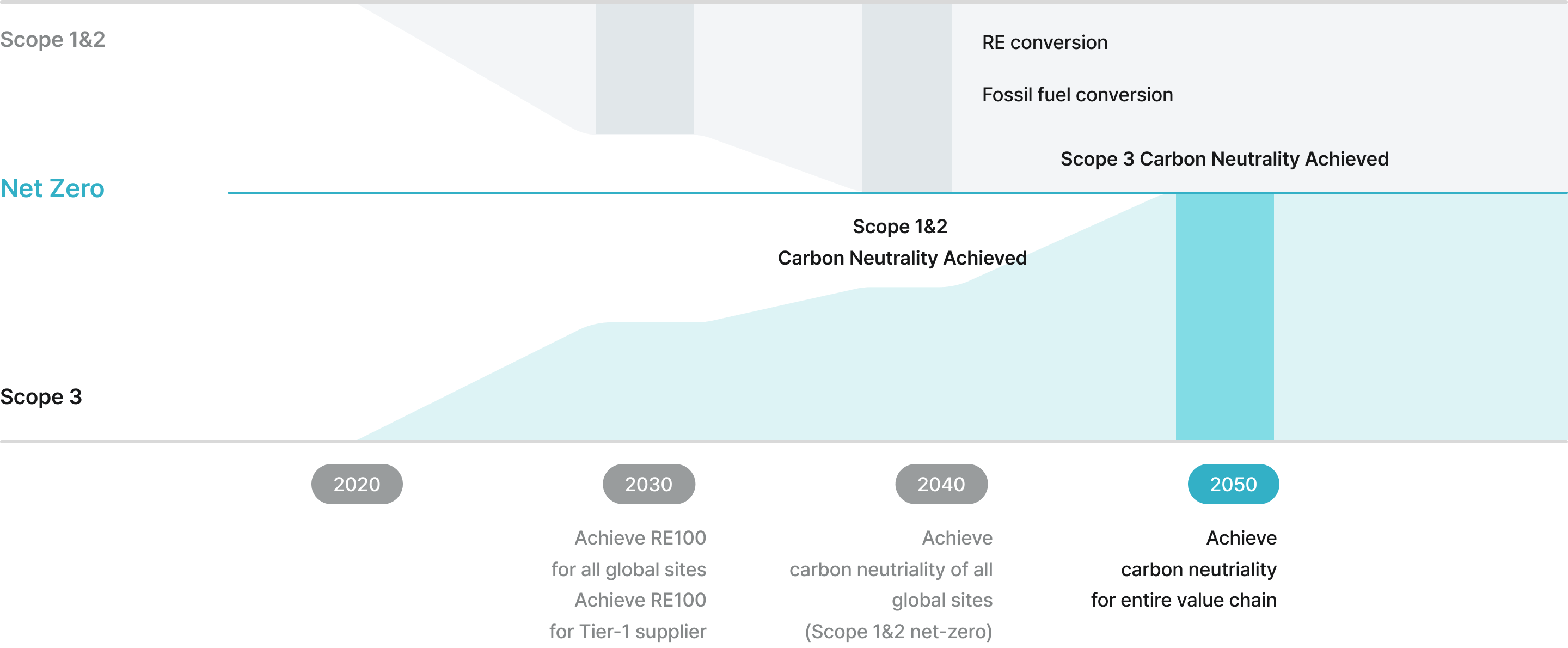

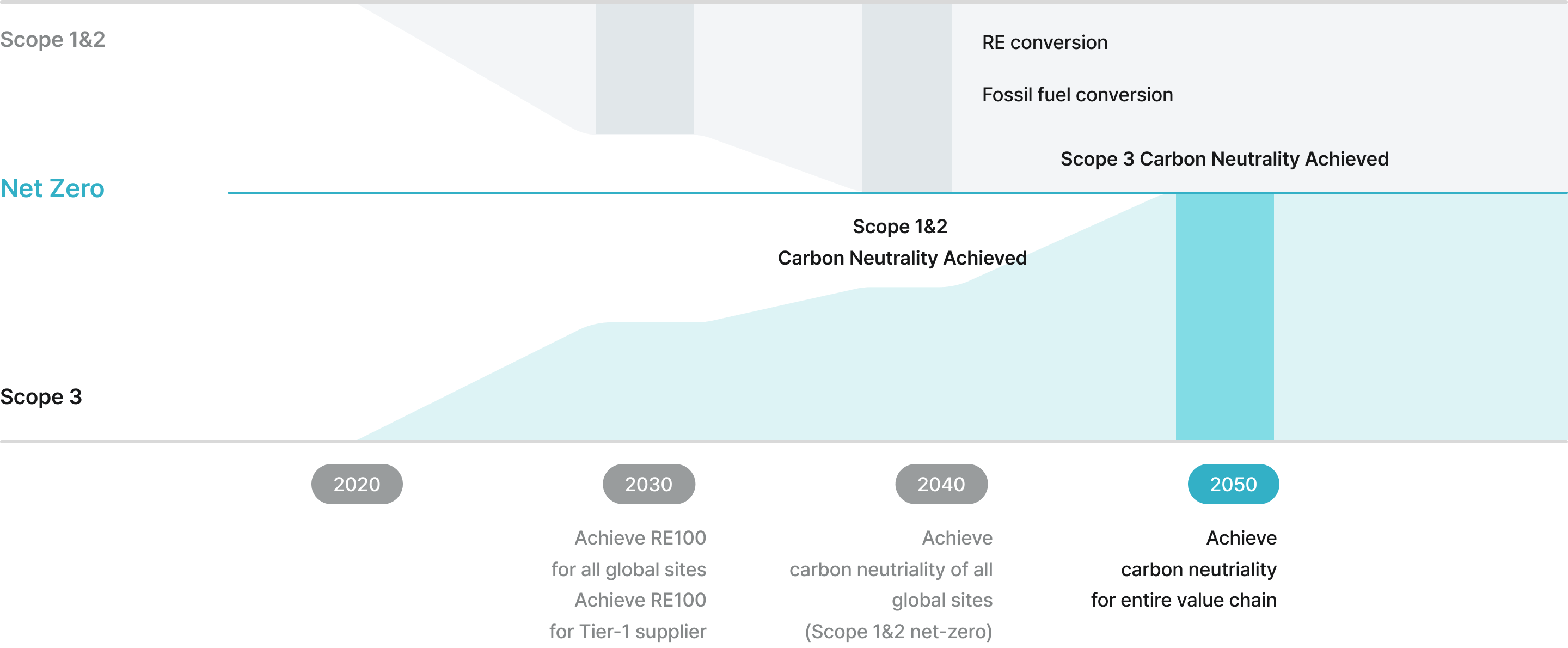

As a global leader in the battery industry driving the transition toward a decarbonized society, LG Energy Solution is actively advancing its climate action initiatives with the goal of achieving carbon neutrality by 2050 and moving further toward carbon negativity thereafter.

&

&

In April 2021, LG Energy Solution was the first global battery manufacturer to join both RE100 and EV100 and declare its commitment to transition electricity sourced in all of its business sites to 100% renewable energy and to transition all of owned and leased vehicles to electric vehicles by 2030.

With a view to accelerating the transition to renewable energy, LG Energy Solution makes efforts to secure stable supply of renewable energy, using varied measures catered to regulatory and power market conditions of each operating site – ranging from generating solar power from photovoltaic facilities installed in manufacturing plants, sourcing renewable energy through renewable energy certificates or green pricing, to exploring more stable and long-term measures such as power purchase agreement to contribute to additionality.

Additionally, we are transitioning corporate vehicle fleets to electric vehicles to achieve EV100, along with improving infrastructure, such as installing EV charging station at our operating sites.

We will continue to explore and find optimal measures to achieve carbon neutrality, taking into account national and local power market structures and cost effectiveness, to achieve both RE100 and EV100.

To achieve carbon neutrality across LG Energy Solution’s operations by 2040, we need to put effort to reduce consumption of primary energy sources such as fuel(e.g., LNG). To this end, LG Energy Solution plans to optimize consumption by improving energy system efficiency, and to convert major heat source systems such as steam boilers to alternative energy sources such as biogas and hydrogen.

The key to achieving carbon neutrality by 2050 is reducing carbon emissions in the supply chain. Ensuring our suppliers’ climate action is essential to reduce our battery carbon

footprint, hence LG Energy Solution intends to engage its suppliers in climate action, ranging from those in Tier-1 to Tier-N. We work to trace and monitor emissions data along our supply chains and support our suppliers to participate in the RE100 transition and carbon reduction activities. In addition, we plan to increase the recycled content in manufacturing with a view to reducing battery carbon footprint as well as contributing to the circular battery ecosystem.

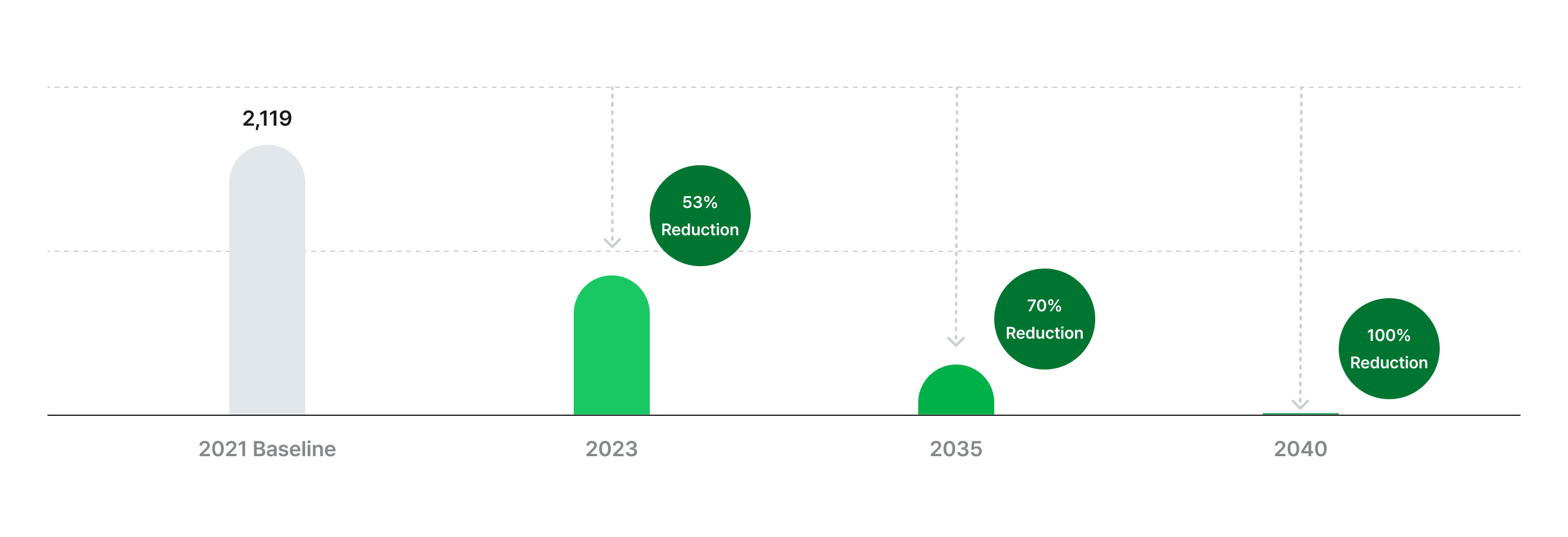

Life Cycle Assessment (LCA) is a technique used to comprehensively assess the environmental impacts of energy and mineral resource use throughout a product’s entire lifecycle, from raw material extraction to disposal (Cradle-to-Grave). LG Energy Solution has adopted LCA since 2019, before spin-off, to evaluate the potential impacts associated with our products. Based on these assessments, we engage with key stakeholders, including customers, to communicate the results. Internally, the results of LCA assessment serve as crucial criteria and tools for calculating the carbon footprint of products, identifying hot spots in raw materials and value chains, and developing medium to long-term strategies for achieving carbon neutrality.

Based on LCA results measured since 2019, LG Energy Solution has obtained Environmental Product Declaration (EPD) certifications-9 newly acquired in 2024, 25 in total. According to the carbon footprint assessments, although results vary depending on product, supplier, and production location, about 36% of total GHG emissions occur during the cell manufacturing process (electrode, cell assembly, activation, module/pack assembly), while about 64% occur during raw material production and transportation. Therefore, in addition to reducing GHG emissions through energy efficiency and renewable energy use in battery manufacturing, we are also managing and supporting GHG reduction efforts by our suppliers.

The certification system that labels product environmental impact information quantified through Life Cycle Assessment (LCA) results is known as Environmental Product Declaration (EPD). It involves third-party certification that inspects the product’s quantified environmental impacts throughout the product’s life cycle, including global warming potential, resource use, water and air pollution, among others. To ensure alignment with global product environmental standards and policies, EPD is developed by applying the internationally recognized standards such as ISO 14020, ISO 14025, ISO 14040 series, ISO/TS 14027, ISO 14046, ISO 14064 series, and ISO 14067.

LG Energy Solution collects and uses personal information as follows for the purpose of providing downloads and responding to inquiries.

Name, Email, Company Name

Consent to Receive Marketing Information

Retained for one (1) year from the date of collection, then destroyed

You may refuse to provide consent; however, in such cases, access to certain content may be restricted.

LG Energy Solution uses personal information to provide useful information such as promotions and newsletters:

Name, Email, Company Name

Consent to Receive Marketing Information

Retained for one (1) year from the date of collection, then destroyed

You may refuse to consent; however, in such cases, content may not be provided.

LG Energy Solution uses cloud systems to manage your information securely. Accordingly, your personal information may be transferred overseas.

Microsoft

United States

Name, Email, Company Name

Data storage and system operation

Transmitted over network immediately upon collection

Retained for one (1) year from the date of collection, then destroyed

You may refuse to consent; however, in such cases, content may not be provided.