Built on safety, durability, and cost competitiveness,

a broad lineup ranging from IT devices to EVs and ESS ensures optimal solutions for customer needs.

Pouch

Core Competitive

Small pouch cells feature high capacity, high power, and ultra-slim design advantages, making them ideal for applications such as smartphones and drones.

-

The Slimmest

-

High energy density

-

Various Sizes

Core Technology

Zigzag Stacking

Advanced cross-stacking technology alternates cathode and anode sheets with separators, enhancing both precision and safety.

High-voltage Mid-Ni NCM Chemistry Core Technology

Single Particle Cathode

Low effective surface area and high structural stability reduce gas generation and extend cycle life at high-voltage.

Electrolyte for High-voltage

Lowering electrolyte oxidation and metal dissolution extends high-voltage cycle life while reducing gas.

Hybrid Conducting Agent

0-Dimensional Conducting Agent:

Higher electrolyte absorption for ionic path. 1-Dimensional Conducting Agent :

High-conductivity electrical path.

Key Advantages of Mid-Ni NCM Chemistry

-

High Energy Density

-

Improved Safety

-

Cost Competitiveness

-

Excellent Durability

High-voltage LCO

Cathode Development Status

LG Energy Solution’s high-voltage LCO cathode technology offers higher unit capacity and operating voltage, increasing energy capacity.

Surface Coating and Doping Process

Minimizes side reactions like cathode lattice distortion and surface reactions from high-voltage, by applying surface coatings and an increased amount of doping materials.

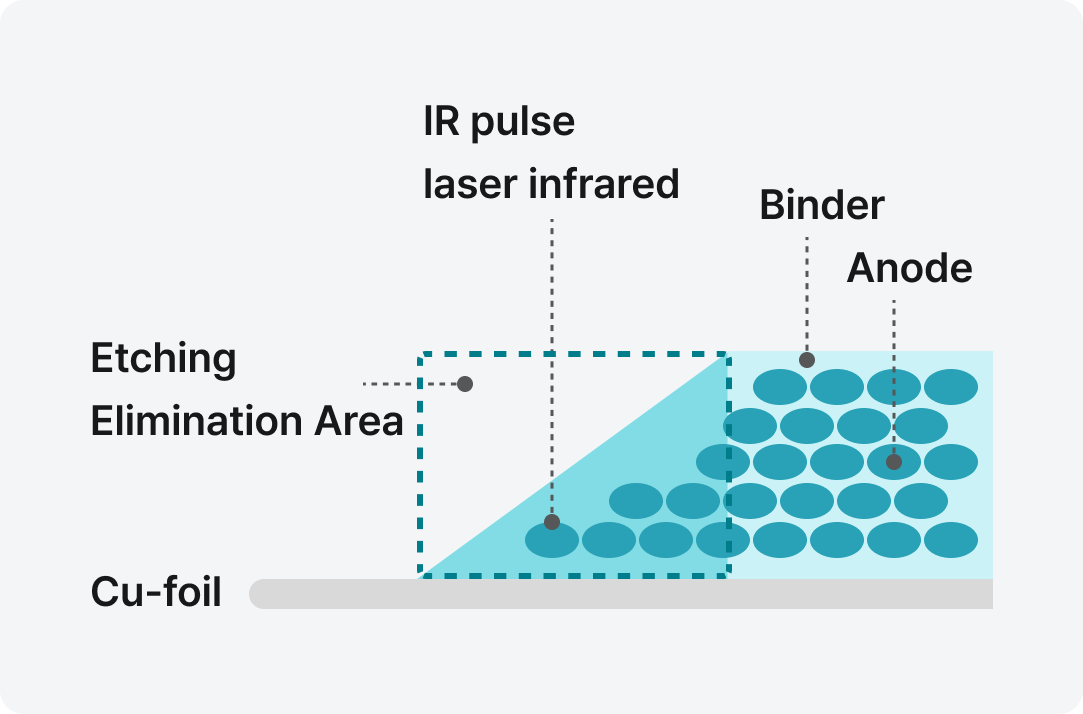

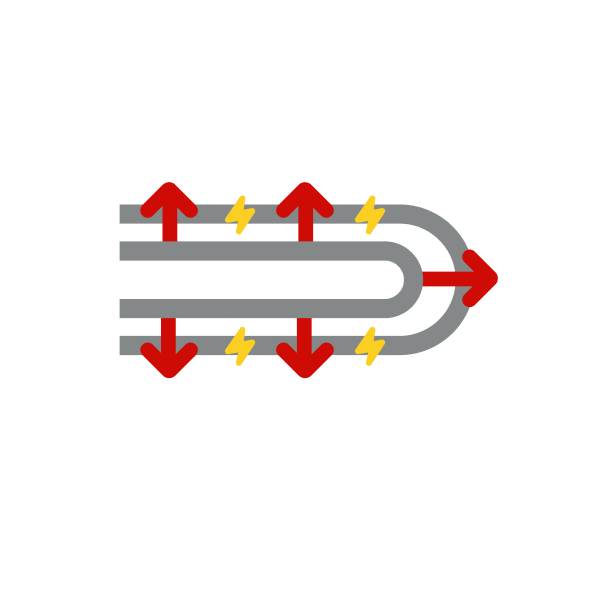

Zero Transition Zone (ZTZ)

Zero Transition Zone (ZTZ) technology prevents top swelling, ensuring stable energy capacity and longer battery life.

What is the ZTZ?

Anode sliding reduces the interfacial capacity between the cathode and anode, affecting energy capacity and charging speed, and leading to top swelling. The ZTZ process enhances the bonding interface between the cathode and anode facing areas and suppresses side reactions in the upper part of the battery by minimizing the anode sliding area through laser removal.

Applications

Production Sites

LG Energy Solution leverages the industry’s largest network of global production sites and extensive manufacturing expertise to deliver customized solutions to customers worldwide.

Major Order History

Core Competitive

With world-class battery technology and global production capabilities, LG Energy Solution leads the global EV market by delivering differentiated products that enhance energy density and driving range.

-

High energy density battery enables driving longer distances.

-

Lightweight battery significantly enhances driving efficiency which is more crucial for commercial vehicles.

-

Maximizing EV operational efficiency with fast charging

-

Enhancing space utilization with flexible battery design

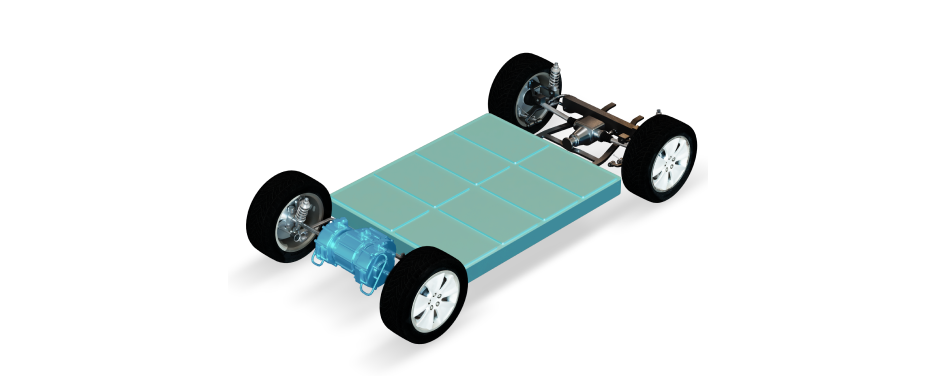

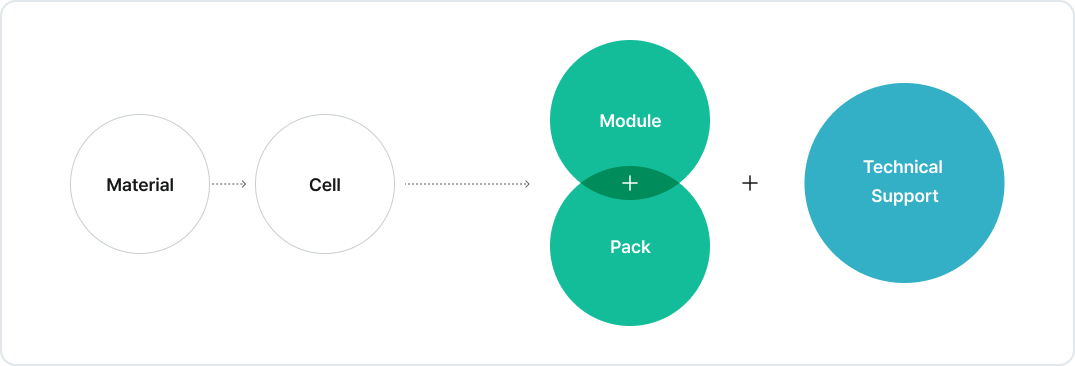

Total Battery Solution

From cells to modules and packs, LG Energy Solution delivers optimized technology solutions built on advanced battery expertise.

Core Technology

Cell

Flexible Sizing Pouch batteries can be freely designed in length and area, enabling increased capacity and highly optimized cell configurations.

-

Uni-direction Cell

-

Bi-direction Cell

-

Short Cell

-

Long Cell

Key Advantages of Mid-Ni NCM Chemistry

High-voltage Mid-Ni NCM is a well-balanced battery solution with high thermal stability and cost competitiveness. Specifically,

pouch-type cells, applied with LG Energy Solution’s 'Lamination & Stacking' technology, achieve higher energy density than competitors.

-

High Energy Density

Mid-Ni chemistry with high-voltage system enhances energy density.

-

Improved Safety

single particle cathode system reduce heat flow in the event of thermal runaway, enhancing thermal stability.

-

Cost Competitiveness

A competitive cost is attained by reducing nickel and cobalt components to decrease dependence on metal price fluctuations..

-

Excellent Durability

Various core technologies reduce gas emissions in high voltage and ensures a longer battery life.

Module/Pack

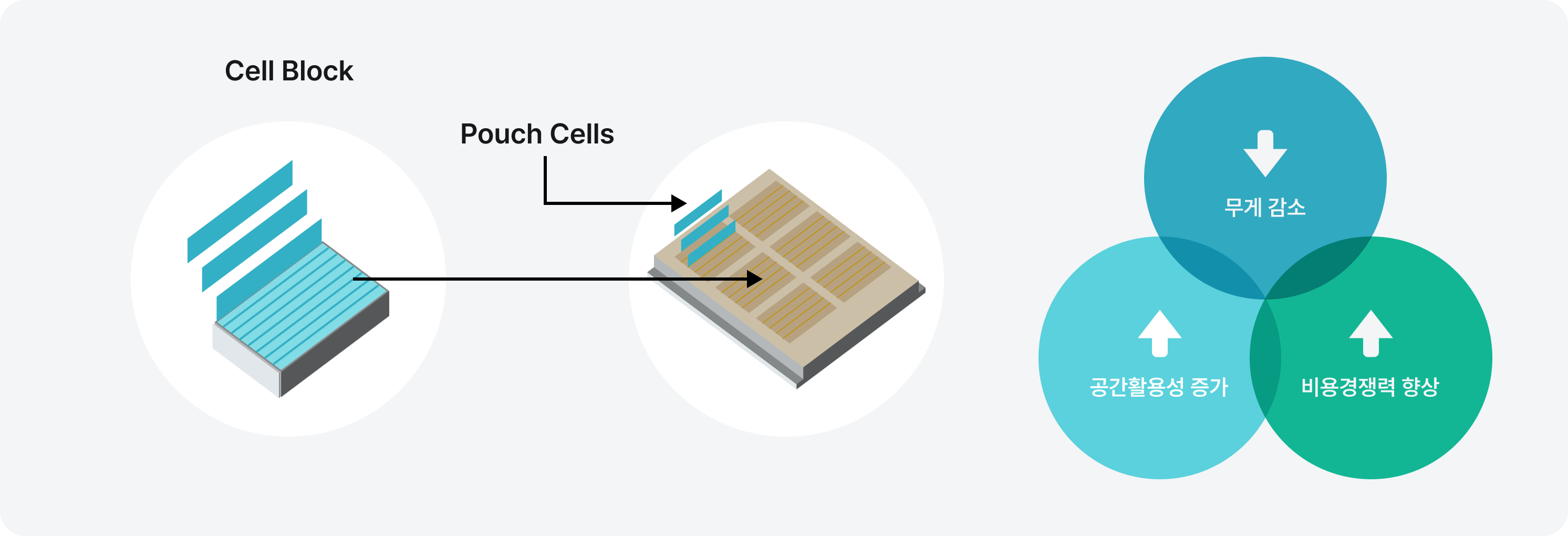

Module to Pack (MPI) With module-to-pack assembly technology, LG Energy Solution delivers battery systems optimized for a wide range of vehicle types.

Cell to Pack(CTP) Pouch-type cells, applied with LG Energy Solution’s 'Lamination & Stacking' technology, achieve higher energy density than competitors.

Dry Electrode Process LG Energy Solution is revolutionizing battery production by commercializing the dry electrode process, lowering processing costs while enhancing performance.

-

Dry Mixing

-

Solid Power Formation

-

Solid Power Formation

-

Roll Pressing

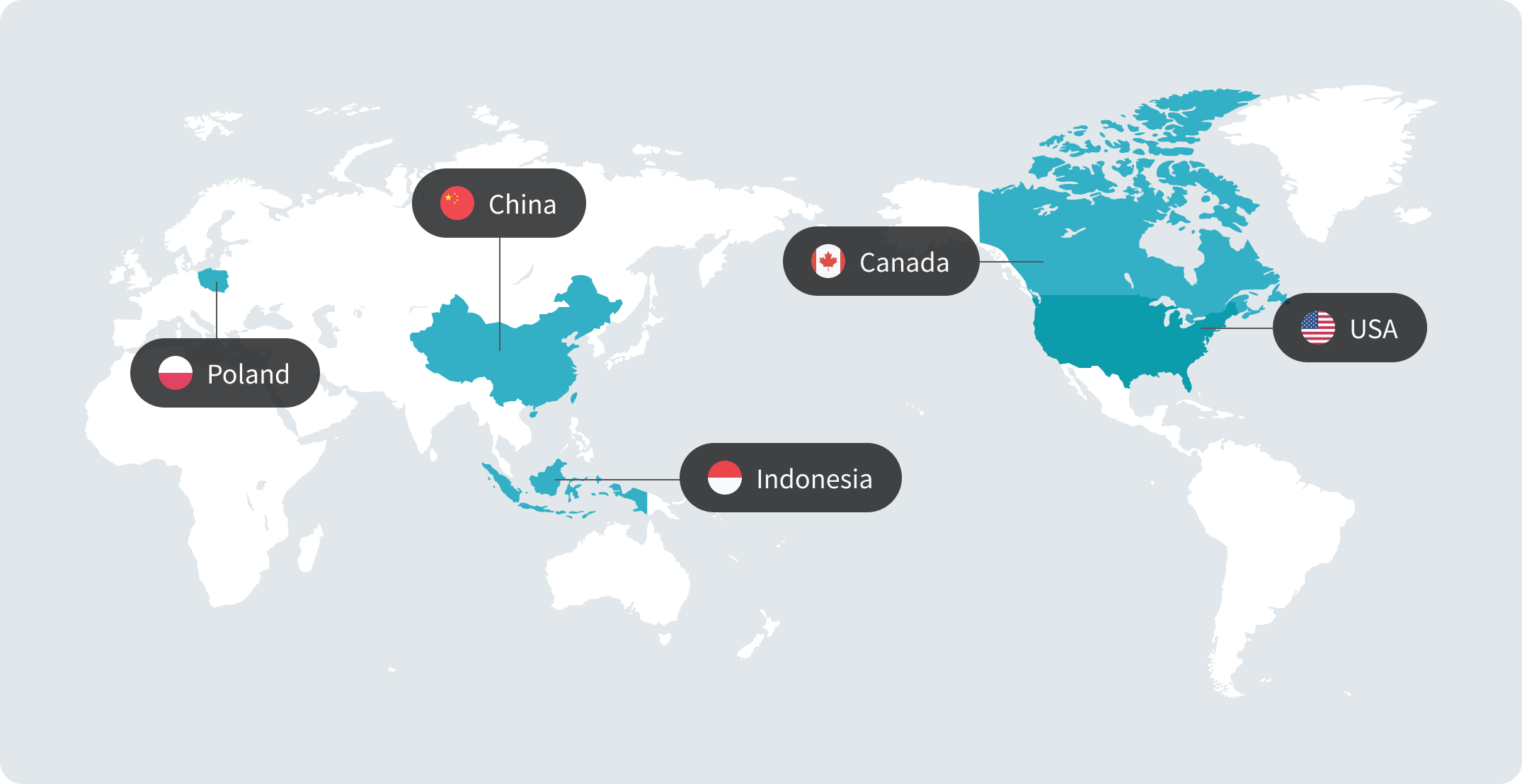

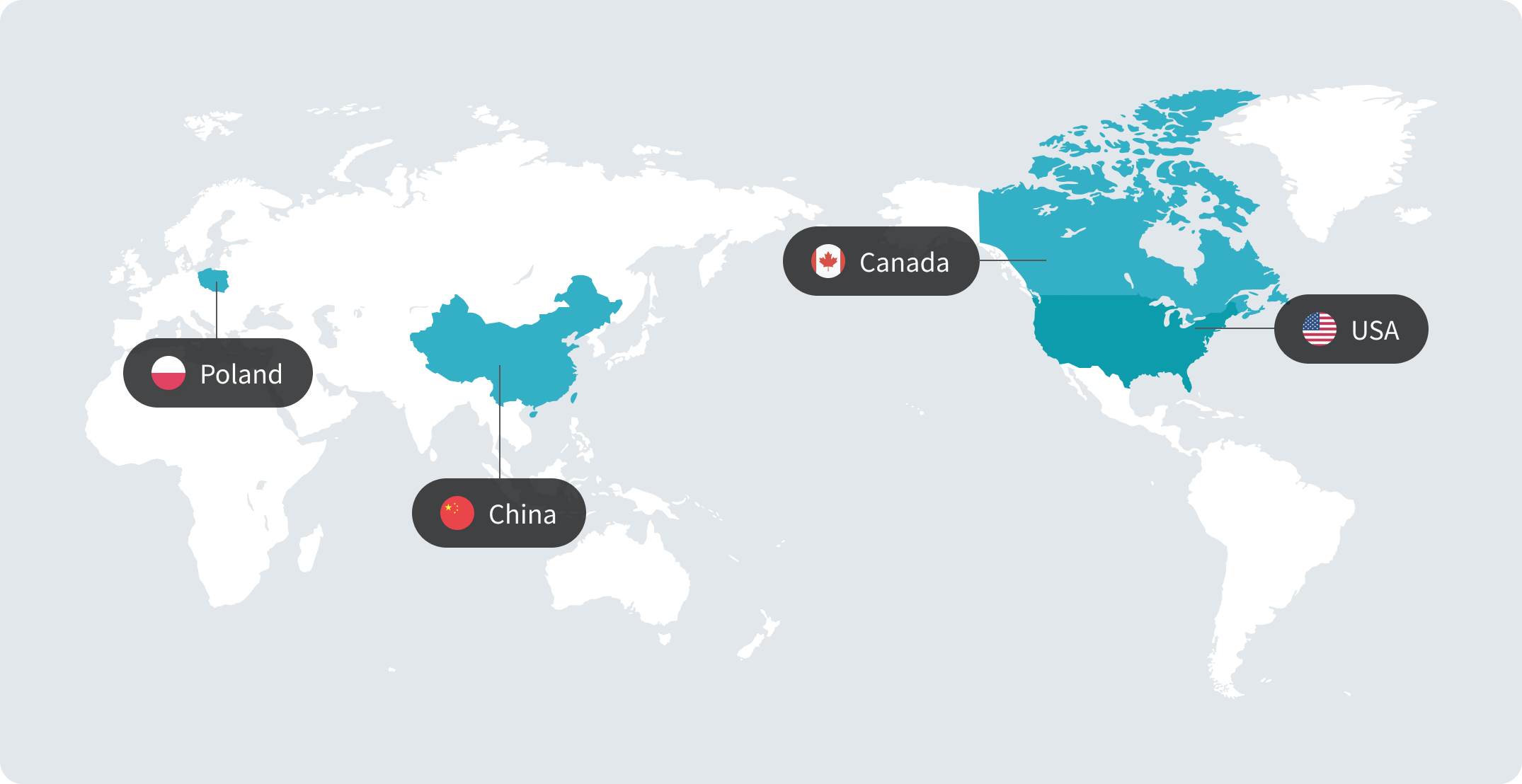

Production Sites

With the industry’s largest global production network across Korea, China, the U.S./Canada, Poland, and Indonesia, along with extensive manufacturing experience, LG Energy Solution ensures swift and effective responses to customer and market needs.

Core Competitive

LG Energy Solution leads the market with a variety of ESS battery products for power grids, commercial & industrial, residential, and UPS use, leveraging superior technology and mass production capabilities

-

First in the Industry to Build Dedicated ESS Battery Production Facilities

With a strong global production network and the industry’s only ESS-exclusive development line,

LG Energy Solution ensures stable battery supply tailored to customer needs. -

Optimized Battery Solutions from NCM to LFP

Our portfolio spans from high-energy-density NCM (Nickel Cobalt Manganese) cells to highly safe and cost-effective LFP (Lithium Iron Phosphate) cells, providing optimized solutions for diverse customer business needs.

-

Reliable Pouch Cell Structure with L&S Process Technology

LG Energy Solution’s proprietary Lamination & Stacking process creates a stable internal electrode structure, significantly improving battery lifespan and reliability.

Core Technology

LG Energy Solution provides the most optimal energy solution for the users using our state-of-the-art energy storage system with a long lifespan and a top-notch quality.

Features

Winding

Limitations in electrode thickness

Lamination & Stacking

Increase in electrode thickness

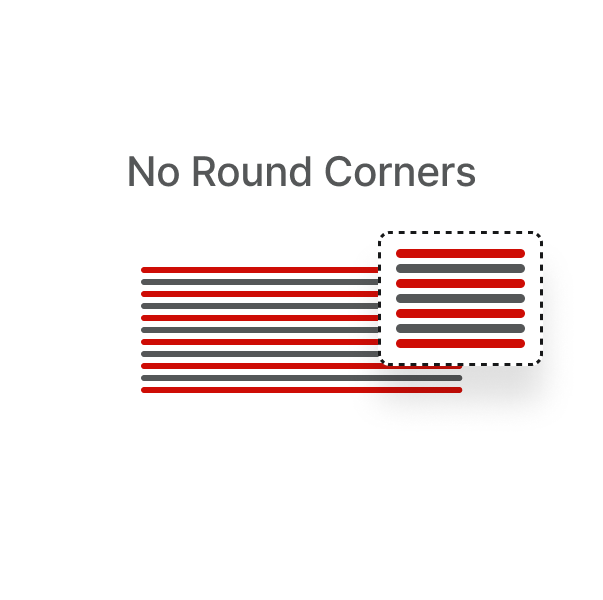

Winding

Lamination & Stacking

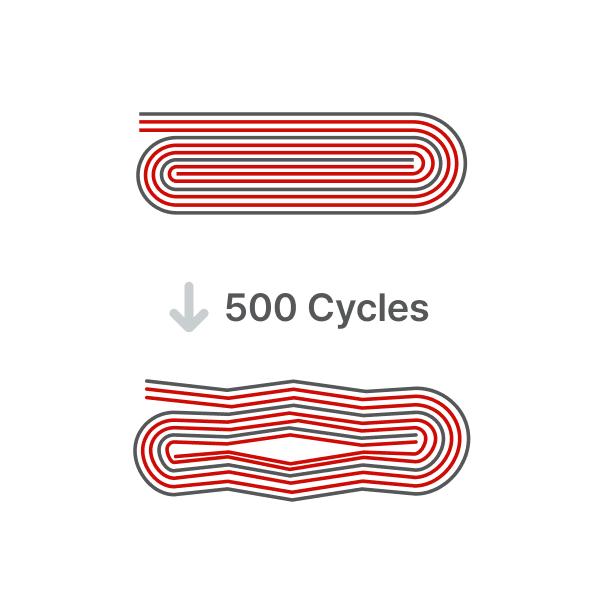

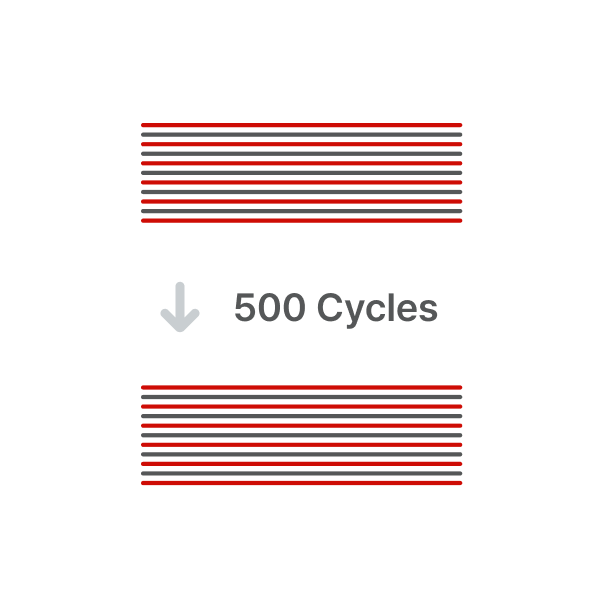

Reliability (after 500 cycles)

Winding

Distortion and delamination occurs

Lamination & Stacking

Keeps initial state

Enhanced Energy Density at the Cell Level

Higher Energy Density High space efficiency

Limited space efficiency

ESS Business Areas

ESS for power grids is installed at thermal power plants, solar and wind power plants, and substations. It has various applications in reducing power load, coupling with renewable power generation, and adjusting power frequency. Commercial ESS is installed in commercial buildings such as offices, schools, and factories, and is used to reduce power load or to couple with renewable power generation.

- Transportable rack system, easy to move and install

- All-in-one LFP containerized solution

- Smart, integrated ESS solution

Cost-optimized Deployment

Reduce on-site installation time and cost with a

Plug & Play

Easy Installation

Saves time and money through rack assembly format

Diverse Product Options

Accommodates client needs through diverse product lines

of cells, packs, and racks

Small Footprint

Lithium-ion battery requiring minimum installation area

A Residential ESS connects to home solar panels, storing daytime energy produced by the solar panels for nighttime use, providing an efficient energy consumption environment.

Total Solution

Leveraging advanced cell technology built on battery material expertise,

LG Energy Solution provides customized ESS solutions—from tailored pack design to BMS-driven safety—that meet diverse customer needs and ensure successful operations.

Local Production

Stable local supply chains with minimized tariff impact

Optimized Solutions

Meeting diverse customer requirements, from inverter-integrated to standalone systems

Quality Assurance

Exceptional durability in any environment, backed by a 15-year warranty

Flexible Design

Customized battery supply from cells to modules and packs

An Uninterruptible Power Supply (UPS) ensures facilities such as data centers and IT/communication hubs maintain a continuous power supply.

- Battery lifespan approximately twice as long as conventional batteries

- Minimized installation footprint through lightweight and compact design

- Higher rate capability and output compared to conventional

batteries of the same capacity - Enhanced maintenance convenience with integrated BMS

Requires only 1m² to install 1MW, enabling fewer racks and greater space optimization for data centers.

JP5’s advanced spark and vent gas control system meets the stringent requirements of UL9540A 4th edition, ensuring superior safety and reliability.

Pre-assembled packs reduce packaging materials, cut transportation costs, and streamline on-site installation.

Self-powered SMPS* delivers electricity within the battery without the need for external power cables or additional AC infrastructure.

*SMPS: Switched Mode Power Supply.

Production Sites

LG Energy Solution has established large-scale production bases in Korea, North America, China, Poland, and Indonesia, ensuring flexible and timely battery supply tailored to customer needs in each region.

Catalog Download

Consent to Collection and

Use of Personal Information

LG Energy Solution collects and uses personal information as follows for the purpose of providing downloads and responding to inquiries.

-

Items Collected

Name, Email, Company Name

-

Purpose of Use

Consent to Receive Marketing Information

-

Method of Provision

Email

-

Retention & Use Period

Retained for one (1) year from the date of collection, then destroyed

-

Right to Refuse and Disadvantage

You may refuse to provide consent; however, in such cases, access to certain content may be restricted.

Consent to Receive

Marketing Information

LG Energy Solution uses personal information to provide useful information such as promotions and newsletters:

-

Items Collected

Name, Email, Company Name

-

Purpose of Use

Consent to Receive Marketing Information

-

Method of Provision

Email

-

Retention & Use Period

Retained for one (1) year from the date of collection, then destroyed

-

Right to Refuse and Disadvantage

You may refuse to consent; however, in such cases, content may not be provided.

Consent to Overseas

Transfer of Personal

Information

LG Energy Solution uses cloud systems to manage your information securely. Accordingly, your personal information may be transferred overseas.

-

Recipient

Microsoft

-

Country

United States

-

Items Transferred

Name, Email, Company Name

-

Purpose of Transfer

Data storage and system operation

-

Method of Transfer

Transmitted over network immediately upon collection

-

Retention & Use Period

Retained for one (1) year from the date of collection, then destroyed

-

Right to Refuse and Disadvantage

You may refuse to consent; however, in such cases, content may not be provided.